How Do Photoionization Detectors Work To Detect Leaks

22nd Apr 2024

Gas leaks pose serious risks, including the potential for explosions, fires, and exposure to toxic substances. Prolonged inhalation of certain gases can lead to severe health issues or even fatalities, depending on the type and concentration of the gas. Gas detectors mitigate these dangers by warning individuals about hazardous gas concentrations, allowing for timely evacuation and intervention.

Photoionization detectors (PIDs) are widely used to detect gas leaks, specifically those involving volatile organic compounds (VOCs) and other hazardous gases. Discover how photoionization detectors work to detect leaks and explore some essential tips for accurate readings.

The Science Behind PIDs

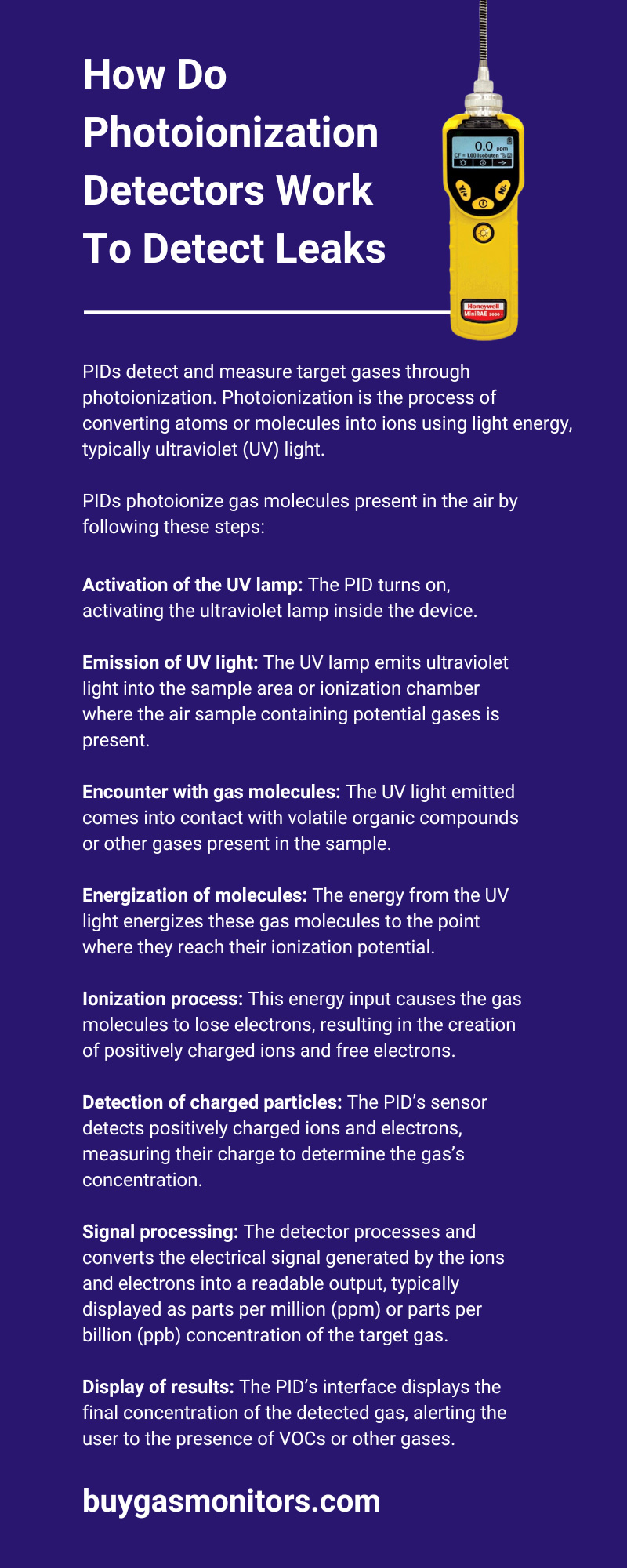

PIDs detect and measure target gases through photoionization. Photoionization is the process of converting atoms or molecules into ions using light energy, typically ultraviolet (UV) light.

PIDs photoionize gas molecules present in the air by following these steps:

- Activation of the UV lamp: The PID turns on, activating the ultraviolet lamp inside the device.

- Emission of UV light: The UV lamp emits ultraviolet light into the sample area or ionization chamber where the air sample containing potential gases is present.

- Encounter with gas molecules: The UV light emitted comes into contact with volatile organic compounds or other gases present in the sample.

- Energization of molecules: The energy from the UV light energizes these gas molecules to the point where they reach their ionization potential.

- Ionization process: This energy input causes the gas molecules to lose electrons, resulting in the creation of positively charged ions and free electrons.

- Detection of charged particles: The PID’s sensor detects positively charged ions and electrons, measuring their charge to determine the gas’s concentration.

- Signal processing: The detector processes and converts the electrical signal generated by the ions and electrons into a readable output, typically displayed as parts per million (ppm) or parts per billion (ppb) concentration of the target gas.

- Display of results: The PID’s interface displays the final concentration of the detected gas, alerting the user to the presence of VOCs or other gases.

Tip: Consider the Target Gas’s Ionization Potential

Each gas has a unique ionization potential, or the minimum energy required to eject an electron from a molecule. Photoionization detectors work to detect gas leaks by comparing the ionization potential of target gases to the energy of the UV light emitted.

PIDs can only detect gases with ionization potentials lower than the energy of the UV light source within them. In other words, if a gas’s ionization potential is higher than the UV light’s energy, the gas won’t absorb the light and the PID cannot detect it.

Components of a PID

To effectively operate and maintain the PID, users must understand its components. Knowing the various parts allows for proper calibration and troubleshooting and ensures the device’s reliability and longevity.

The core components of a PID include the UV lamp, the ionization chamber, and the detector. The UV lamp serves as the source of ultraviolet light necessary to photoionize the gas molecules present in the sample air. Positioned within the ionization chamber, this lamp emits photons at a specific energy level tailored to ionize a wide range of VOCs and other gases.

Consider the other components of the PID and their functions:

- Amplifier: Boosts the electrical signal from the sensor for clearer analysis and reading.

- Display or output interface: Shows the concentration of gases detected in an understandable format for the user.

- Power source: Supplies the necessary energy to operate the UV lamp and other components of the PID.

- Sample pump: Draws air or gas samples into the ionization chamber for testing.

- Filter: Removes dust and moisture from the air sample before it enters the ionization chamber to ensure accurate readings.

Types of Gases PIDs Detect

Photoionization sensors detect a wide array of gases and vapors, making them versatile for applications in numerous industries. Commonly detected substances include benzene, toluene, xylene, and other volatile organic compounds prevalent in the chemical manufacturing, oil and gas, and environmental monitoring sectors. PIDs can also detect a variety of other gases with suitable ionization potentials, such as some inorganic substances like ammonia, hydrogen sulfide, and certain chlorinated hydrocarbons.

VOCs are a large group of chemicals that evaporate easily at room temperature, which significantly increases their potential for overexposure and environmental contamination through air pollution. These compounds can have significant health impacts, ranging from short-term effects like eye irritation to long-term effects like damage to the liver, kidneys, and central nervous system.

Determining Specific Gas Detection Capability

To determine whether your PID can detect a specific gas, first check the gas’s ionization potential (IP) and compare it to the UV lamp energy output in your PID. The PID can only detect gases with an IP lower than the lamp’s photon energy.

Consult the manufacturer’s documentation or specification sheets, which typically list the gases the device can detect along with its detection ranges. Additionally, you can contact the manufacturer or a knowledgeable distributor for clarity on your PID’s capabilities and any necessary adjustments or calibrations for specific gas detection.

Device Maintenance

Maintaining a photoionization detector is crucial for ensuring its accuracy and reliability in detecting volatile organic compounds and other gases. Regular maintenance involves checking and cleaning the sensor and lamp.

Wear and tear on the PID can lead to inaccurate readings or even device failure. To maintain the device’s performance over time, replace parts according to the manufacturer’s guidelines. Keeping a maintenance log can help users predict when parts might need replacement or recalibration, ensuring continuous and reliable operation.

As with other gas detectors, users should calibrate the PID according to the manufacturer’s recommended timeline. Over time, a PID’s sensitivity can drift due to factors such as aging of the UV lamp, exposure to certain gases, or environmental conditions. Regular calibration against known concentration standards ensures the PID provides accurate readings.

Advantages and Limitations of Using PIDs

PIDs’ functionality makes them essential for monitoring leaks in manufacturing and emergency settings. Their rapid response times enable users to swiftly assess the environment and make informed decisions on the spot. Additionally, PIDs’ portability allows for easy transport and use across various locations, making them a versatile tool.

However, the accuracy of PIDs can be influenced by several environmental factors, including humidity, temperature, and the presence of other gases. To overcome these environmental challenges, users can equip their PIDs with built-in correction factors or external software that adjusts readings based on current humidity and temperature conditions, enhancing accuracy. Implementing pre-filters can also help by removing moisture and other interfering gases before the sample reaches the sensor, reducing the likelihood of false readings.

Photoionization sensors detect VOCs and other hazardous gases, employing the process of photoionization to offer rapid, accurate measurements. Their versatility and adaptability to various environmental conditions make them invaluable for detecting leaks. Users can maintain the accuracy of these devices through regular maintenance and calibration, as well as by understanding their operational principles and limitations. Invest in a PID for fast and accurate gas leak detection.