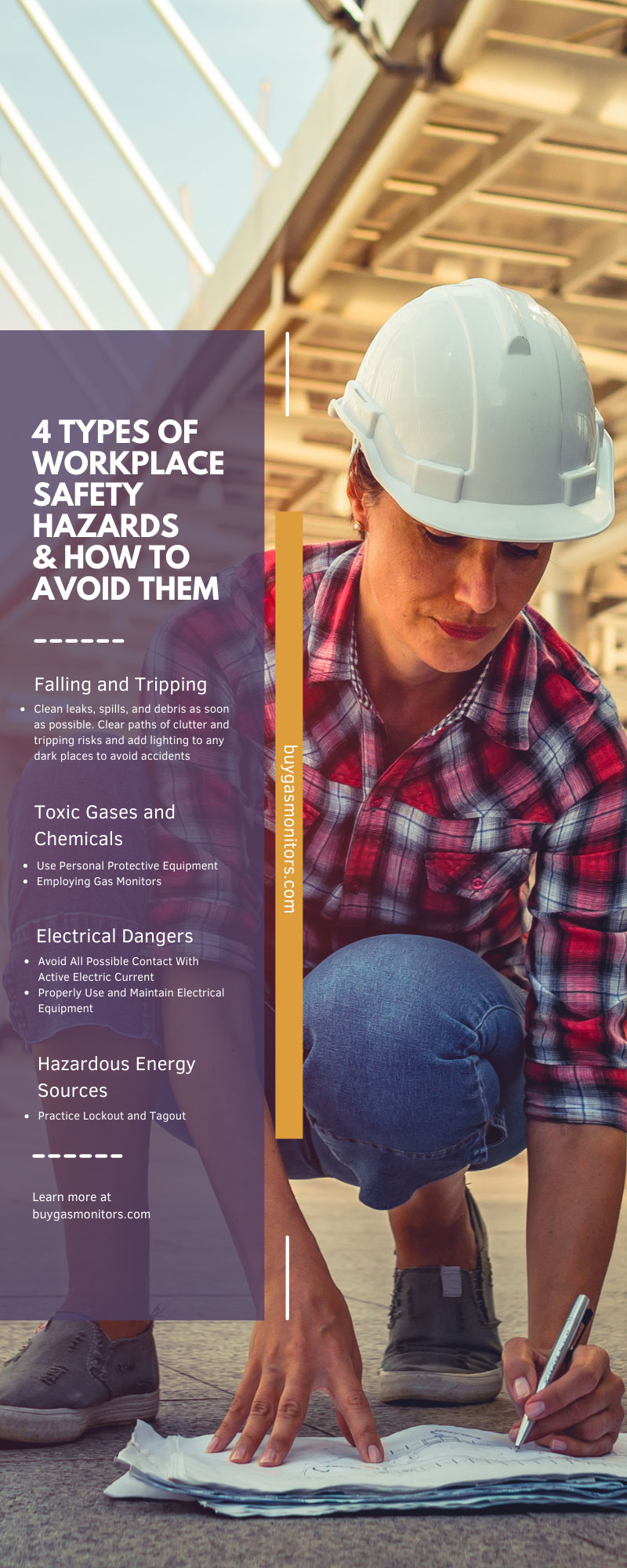

4 Types of Workplace Safety Hazards & How To Avoid Them

Posted by William Kimmell on 9th Dec 2021

Keeping employees safe should be the number one priority of any business. Fortunately, most occupational accidents and incidents are avoidable if you take reasonable and practical measures such as educating personnel on risks they need to be on the lookout for. Below you will find our guide on four types of workplace safety hazards and how to avoid them.

Falling and Tripping

You may believe that falling dangers only exist in settings where people work at great heights. The reality is that practically every business has potential risks such as falling, sliding, and tripping. Recognizing a potential hazard allows you to equip employees with the knowledge they need to protect themselves from significant injury.

Examples of fall and tripping hazards include the following:

- Platforms without suitable railing

- Fragile or damaged ladders

- Spills that aren’t cleaned up right away

- Moving heavy objects

- Staircases

- Debris left in walkways

Perilous Surface Conditions

Some of the most common causes of slips, trips, and falls are improperly maintained walkways and surfaces. These can include slick, sloping, or wet flooring, poorly lit pathways, or cluttered areas. Clean leaks, spills, and debris as soon as possible. Clear paths of clutter and tripping risks and add lighting to any dark places to avoid accidents.

Elevated Heights

Working alongside stairwells and ladders can be hazardous if you're not careful. While taking the stairs, remind employees to go at a steady pace and grasp the railings when they’re ascending or descending. Clean up any debris or leftover tools and materials immediately. If you or employees are using ladders, make sure all fasteners, rungs, and steps are in excellent working order. Ensure the ladder is placed on a flat, sturdy platform.

Toxic Gases and Chemicals

Chemical and toxic compounds can cause various health and physical problems such as inflammation, carcinogenic effects, corrosion, flames, and explosions. Typically, the greater the volume of a substance entering one’s body, the more significant the impact is. This is referred to as the "dose-response relationship.”

Four factors determine the dosage you get by inhaling a harmful substance. They are:

- The concentration of the substance in the atmosphere

- How deeply you’re breathing

- The volume of the substance that lingers in your lungs and enters your circulation

- The amount of time you get exposed to the substance

Limit your exposure to harmful substances as much as possible. The threshold level is the lowest concentration that may cause harm, and it varies per chemical. Therefore, each workplace must ensure they have safeguards in place to protect themselves from the unique, dangerous contaminants.

Use Personal Protective Equipment

Employers need to have a comprehensive program regarding the training in the use and mandatory wearing of Personal Protective Equipment (PPE), including respirators, gloves, eye-protection, splash shields, maximum skin coverage, and more. All equipment needs to be of a material that can't get penetrated by the chemical you're handling.

Employing Gas Monitors

Gas detection and monitoring systems are employed as safety systems to warn employees about the risk of deadly gas overdose and asphyxiation (due to a lack of oxygen or combustion due to flammable gases.) These are critical in reducing exposure as much as possible and enabling people to act fast when potential hazards arise. The quicker you can identify a safety issue, the better.

Electrical Dangers

Electrical hazards are significant workplace dangers that expose employees to burns, electrocution, jolts, arc flash and arc blasts, flames, or explosions. You experience electric shock when your body becomes part of an electric circuit. For example, both hands touch a live wire or a metallic component that’s become electrified because of contact with an electrical conductor).

Both overhead and underground power lines are exceedingly dangerous due to the extraordinarily high voltage they carry. While electrocution can be fatal and is your primary risk, additional risks include burns and falling from elevated heights due to shocks.

Another type of electrical danger is when worn extension and flexible cords loosen or expose wires underneath, creating a potential hazard. Additionally, you risk exposing yourself to endangerment when you improperly use and maintain outlets, cords, plugged-in devices, and connectors.

Avoid All Possible Contact With Active Electric Current

The best way to prevent safety risks concerning electrical hazards is to stay away from things with active electric currents. Non-qualified individuals should never deal with or touch electrical currents larger than 50 volts. If you must work in the same space as an electrical danger or equipment that operates on more than 50V, keep a safe distance away from it. Always make sure that you close every panel door and that no exposed wires surround your work area.

Properly Use and Maintain Electrical Equipment

Use intelligent handling procedures to reduce your risk of electrocution and other dangers when running electrical equipment. Unplug electrical cords by the head and never tug or overstretch them. If you can’t close cabinets or fully enclose an electrical hazard, then place barriers, shields, or insulating material near them.

Hazardous Energy Sources

Energy sources in machinery such as electricity, hydraulic, pneumatic, chemical, and thermal can be dangerous to employees. Such energy sources can become deadly during equipment and machinery servicing and maintenance when unexpected restarts suddenly release stored energy. Potential injuries from energy hazards include electrocution, burning, crushing, cuts, lacerations, disfigurement, or fracturing bones.

Practice Lockout and Tagout

You must follow standard lockout and tagout protocols by disconnecting the energy supply from equipment and implementing the required devices to avoid unexpected restart or re-energization. While every workplace is slightly different, start by informing all employees of the equipment shutdown and then finding and isolating the hazardous energy sources. Once that’s done, lock and tag them and ensure you’ve effectively isolated the equipment.

When You Can’t Perform Lockout

In certain circumstances, applying lockout is impractical, and you need to take other measures to limit risk to others. You may implement restrain mechanisms such as blocks, chocks, pins, bars, chains, or cribbing. Isolation is another potential process as you can use inflated bladders or blanks and blinders to separate workers working near energy sources.

We hope this guide on four types of workplace safety hazards and how to avoid them can help you create and implement practical protection measures in your own organization or personal worksite. TG Technical Services offers industrial gas sensors to alert employees of the presence of toxic gas along with other essential safety equipment to protect yourself and your employees from workplace hazards. Feel free to contact us with any questions about our products.